As energy costs fluctuate and climate goals intensify, more households, businesses, and remote facilities are pursuing off-grid power solutions. These systems not only provide resilience against grid instability but also help achieve long-term energy independence. In 2025, the growing sophistication of battery storage technologies is making it easier to combine energy autonomy with environmental responsibility. But can off-grid systems truly deliver reliable, sustainable energy?

Explore the latest off-grid power storage solutions of 2025 that empower energy independence and promote sustainable living.

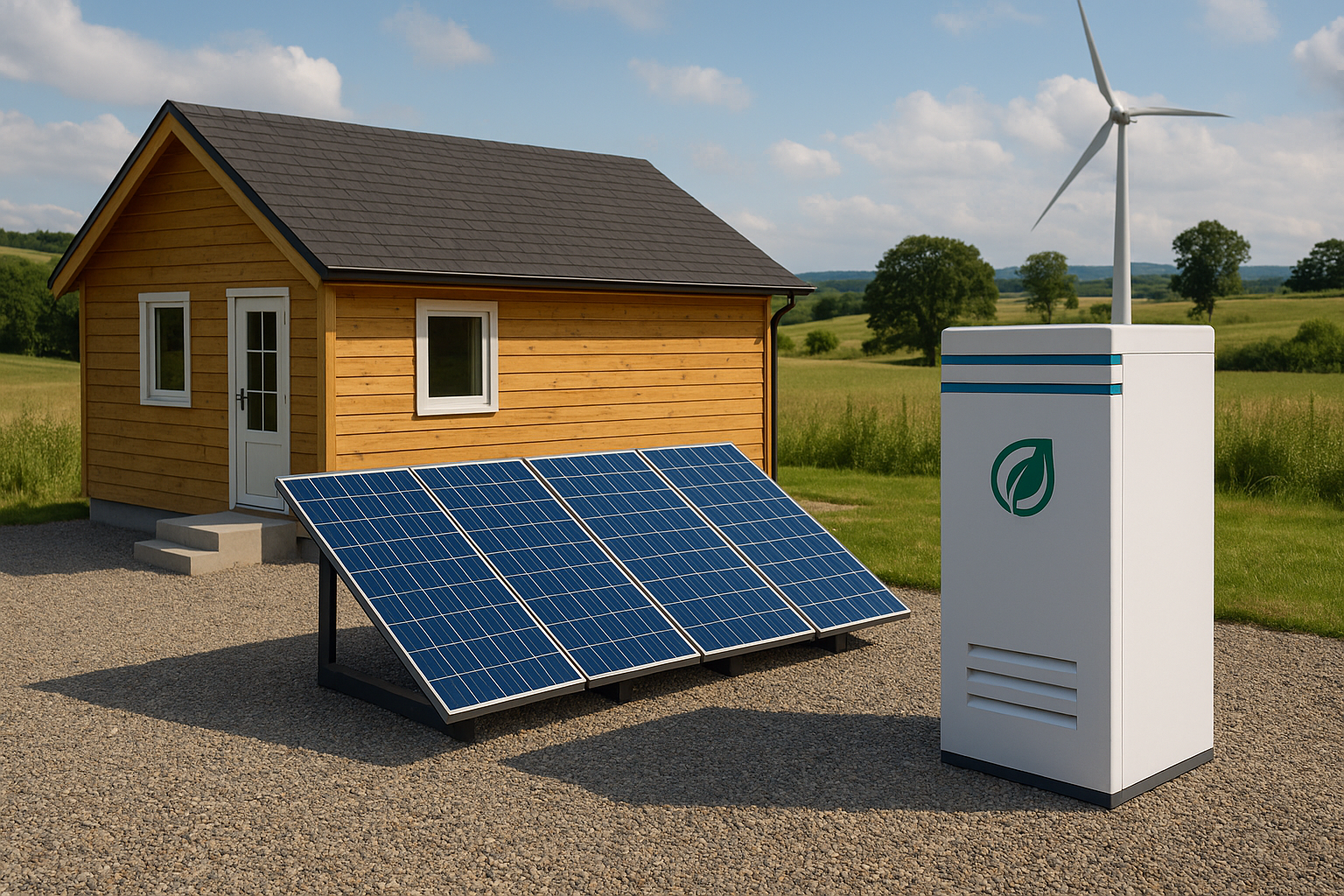

Off-grid power storage systems are increasingly paired with renewable energy sources like solar and wind to create self-sustaining power ecosystems. By storing excess electric power during the day for use at night or during outages, these systems ensure energy conservation, minimize reliance on fossil fuels, and support green energy goals. The synergy promotes both environmental stewardship and power saving strategies.

Discover how cutting-edge storage systems can revolutionize your approach to clean energy and sustainable living.

Understanding Off-Grid Power Storage Systems

Off-grid power storage systems are energy infrastructures designed to operate independently of traditional utility grids. They use renewable energy sources such as solar panels or wind turbines to generate electric power, which is then stored in batteries for use when generation dips or demand peaks. These systems are essential in remote areas or in situations where grid access is unreliable or unavailable.

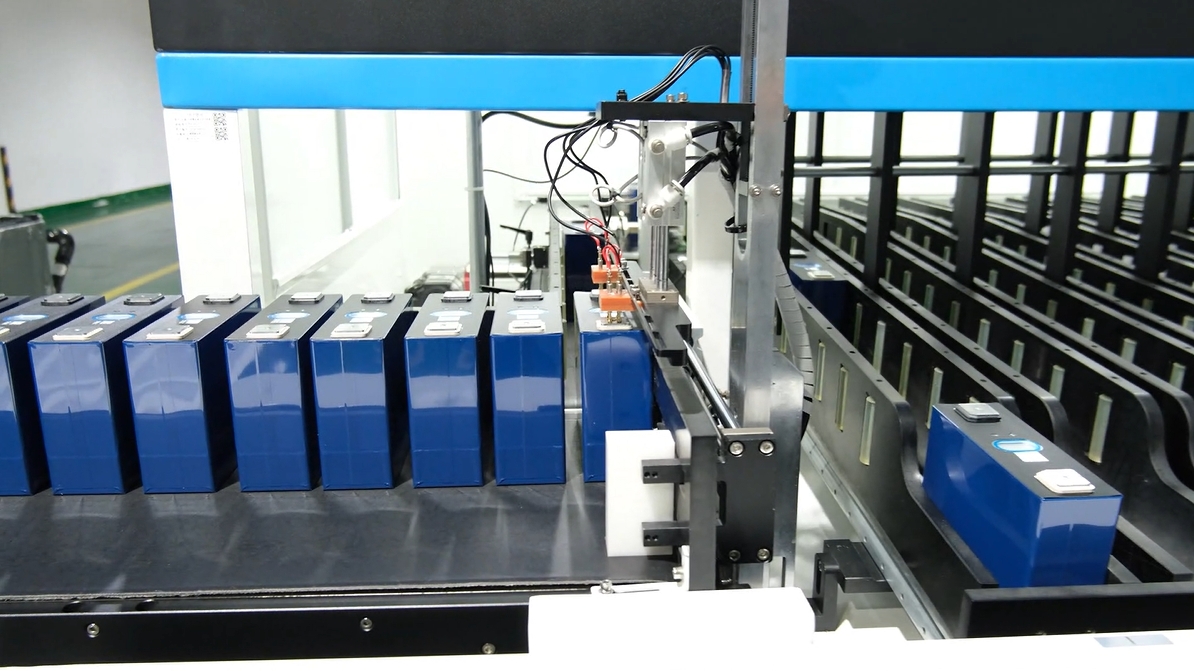

A typical off-grid setup includes a renewable energy source, a charge controller, an inverter, and a battery pack. The battery pack—often composed of lithium-ion or other advanced battery types—is the core of the storage system, enabling consistent power supply regardless of weather or time of day. Unlike grid-tied systems, off-grid installations must be carefully designed to meet specific load requirements, as backup from the grid is not an option.

New energy solutions like flow batteries and solid-state batteries offer improved performance, longer life cycles, and better environmental profiles. Advanced battery backup systems are also integrated to support critical loads during extended periods of low generation. For businesses or communities looking to achieve true energy independence, these systems form a robust foundation.

Moreover, smart controllers and IoT-based monitoring allow users to track consumption, optimize performance, and ensure efficient energy saving and energy conservation. As clean energy technologies continue to evolve, off-grid systems are becoming increasingly scalable, affordable, and viable for wider adoption.

Benefits of Off-Grid Power Storage for Energy Independence

One of the main drivers for off-grid storage is the desire for complete energy independence. Whether for a rural village, a disaster-prone region, or a self-sustaining home, being off-grid eliminates reliance on external electric utilities. In 2025, this is not just a lifestyle choice—it’s a strategic energy and financial decision.

Financially, users gain control over energy pricing by avoiding time-of-use charges and demand spikes. This power saving can translate into substantial long-term energy savings, especially in areas with high utility costs or unreliable grid infrastructure. Coupled with clean energy sources like solar panels or micro wind turbines, these systems reduce monthly expenses while promoting green power consumption.

From an environmental perspective, going off-grid aligns with global goals for renewable energy adoption and green energy transformation. Storing solar power during the day and using it overnight drastically reduces the use of diesel generators or coal-based electricity, slashing greenhouse gas emissions.

Operationally, off-grid systems offer unmatched resilience. Natural disasters, cyberattacks, or grid overloads pose no risk to self-powered facilities. Modern battery backup systems ensure essential appliances and services stay online during emergencies.

Finally, off-grid systems give users autonomy and peace of mind. For communities and companies with sustainability targets or ESG mandates, off-grid setups demonstrate real-world action toward energy conservation and new energy adoption.

Top Off-Grid Power Storage Technologies in 2025

In 2025, a variety of technologies enable off-grid systems to perform efficiently across diverse conditions. Each solution offers unique benefits in terms of storage capacity, lifespan, cost, and environmental impact.

1. Lithium-Ion Battery Packs

Still the most widely adopted, lithium-ion battery packs are valued for their high energy density and relatively low maintenance. Compact and scalable, they are ideal for homes and small businesses with moderate energy needs. Advanced lithium chemistries have increased lifespan and safety features, making them a reliable choice for off-grid setups.

2. Flow Batteries

Flow batteries are becoming increasingly common in off-grid applications that require longer-duration storage. These systems store energy in liquid electrolytes housed in separate tanks. They offer high cycle life, low degradation, and easy scalability—making them ideal for community microgrids and agricultural operations.

3. Solid-State Batteries

Emerging solid-state technology eliminates the flammable liquid electrolyte found in traditional batteries, making them safer and capable of higher energy density. Though still costly, pilot programs in 2025 have demonstrated their promise for long-term off-grid applications.

4. Hydrogen Storage Systems

Hydrogen fuel cells offer another clean energy option, especially for large-scale or industrial use. They generate electric power by converting stored hydrogen into electricity without combustion, emitting only water vapor. These systems can store excess green power from solar or wind sources and release it on demand.

5. Hybrid Systems

Many 2025 systems combine multiple technologies—for instance, pairing a lithium-ion battery pack with a flywheel or hydrogen generator. These hybrid configurations provide both short-term response and long-duration support, maximizing reliability.

Smart software also plays a critical role, helping users forecast demand, manage loads, and integrate with renewable energy sources for efficient energy saving and utilization.

Cost Analysis and Return on Investment

While off-grid systems have historically been considered expensive, prices have declined significantly in 2025 thanks to advancements in battery technology and mass production. The total cost of an off-grid solution depends on system size, storage capacity, and energy source integration.

Initial Costs

- Small residential systems: $10,000–$25,000

- Medium commercial systems: $50,000–$200,000

- Large industrial systems or microgrids: $500,000+

The most significant cost drivers are the battery pack, inverter, and renewable energy generation equipment. Battery backup options add cost but are vital for reliability.

Return on Investment (ROI)

Despite high upfront costs, off-grid systems often achieve payback within 5 to 10 years due to:

- Eliminated utility bills

- Incentives for clean energy (tax credits, grants)

- Monetization through carbon offsets

- Improved operational resilience

- Participation in local energy trading or microgrid networks

Additionally, many regions in 2025 offer government subsidies and loans for installing green energy systems. Financial institutions are increasingly supporting new energy infrastructure due to growing awareness of environmental risk.

Ultimately, ROI improves when systems are designed to match actual consumption and include smart controllers for optimal energy conservation. Regular maintenance and proper scaling are key to long-term performance.

Future Trends in Off-Grid Power Storage

The future of off-grid energy in 2025 and beyond is being shaped by several transformative trends:

1. Artificial Intelligence Integration

AI-driven energy management platforms are now standard in off-grid systems. These tools analyze weather patterns, usage behavior, and storage efficiency to automate energy flow, extend battery life, and lower costs.

2. Modular and Scalable Designs

Manufacturers are introducing plug-and-play battery modules that make it easier to scale up as needs grow. This reduces installation complexity and allows users to customize their systems over time.

3. Repurposed EV Batteries

A growing number of off-grid systems are using second-life electric vehicle battery packs. These recycled components offer affordable storage while contributing to the circular economy and reducing electronic waste.

4. Integration with Microgrids

Off-grid systems are being linked to local renewable energy microgrids, enabling energy sharing, peer-to-peer trading, and backup support. This hybrid approach offers the best of both autonomy and collaboration.

5. Greater Regulatory Support

Governments around the world are expanding incentives for green power, off-grid infrastructure, and disaster-resilient energy systems. From carbon credits to zero-interest loans, public policy is accelerating market growth.

The direction is clear: future off-grid systems will be smarter, cleaner, more resilient, and deeply integrated with renewable energy networks.

Empower your future with energy independence—contact us to design your custom off-grid power solution today.