Lithium battery energy storage systems play a crucial role in today’s renewable energy infrastructure. As global demand increases, so does the need for manufacturing consistency, performance reliability, and user safety. At the heart of delivering safe, long-lasting, and efficient energy storage systems lies a rigorous quality control (QC) framework. From selecting raw materials to final rack-level system testing, quality assurance in battery production ensures each component performs optimally throughout its lifecycle. This article provides an in-depth examination of the processes that safeguard lithium battery quality in energy storage manufacturing.

What Are the Key Quality Control Steps in Lithium Battery Manufacturing?

Key quality control steps include raw material testing, cell-level inspection, electrode coating precision, formation cycling, safety validation, and final rack-level battery testing.

In lithium-ion battery production, quality assurance directly affects battery performance, longevity, and safety. Even minor inconsistencies in cell manufacturing can lead to overheating, reduced capacity, or catastrophic failure. Precision in the battery cell inspection process and adherence to international energy storage manufacturing standards are essential to mitigate risks, ensure compliance, and maintain end-user trust in large-scale deployments.

Explore each phase of the production line to discover how defects are prevented and high-performing battery systems are delivered.

The Importance of Quality Control in Lithium Battery Production

Lithium battery quality control is critical to ensuring safety, performance, and consistency across every unit manufactured. Energy storage systems operate under variable environmental conditions and high load cycles. Inadequate QC increases the risk of thermal runaway, capacity loss, or early battery failure.

An effective QC process detects flaws before they propagate across production lines, preventing costly recalls or system failures in the field. For instance, rigorous monitoring during electrode coating ensures active materials are distributed evenly, a key factor in energy density and cycle life.

In energy storage applications, minor issues such as moisture intrusion or particle contamination during assembly can significantly impair battery efficiency and stability. This is particularly true in prismatic cell quality control, where the layered structure must remain uncontaminated and evenly packed to meet performance metrics. A comprehensive quality assurance process upholds the reputation of battery brands and ensures system integrators and end-users receive reliable, long-lasting energy storage solutions.

Additionally, regulatory expectations are increasing as lithium-ion energy storage systems scale to meet the demands of electric vehicles, commercial storage applications, and decentralized power grids. Inconsistent or substandard manufacturing not only undermines performance but also poses serious safety risks. Hence, companies that invest in rigorous QC frameworks distinguish themselves in the global market, enhancing their credibility and customer retention.

From Raw Materials to Final Testing: The Full QC Process

The battery production line QC process spans multiple stages, from sourcing raw materials to final product testing. Each step is engineered to identify and eliminate inconsistencies:

- Raw Material Testing: Lithium, nickel, cobalt, and graphite must meet strict purity levels. Impurities are tested using spectroscopy and chromatography methods. Each material batch is traced and logged to maintain quality provenance.

- Electrode Preparation: Electrode coating thickness, adhesion, and homogeneity are monitored via automated optical inspection and laser measurement systems. Any deviation can alter the battery’s electrochemical behavior.

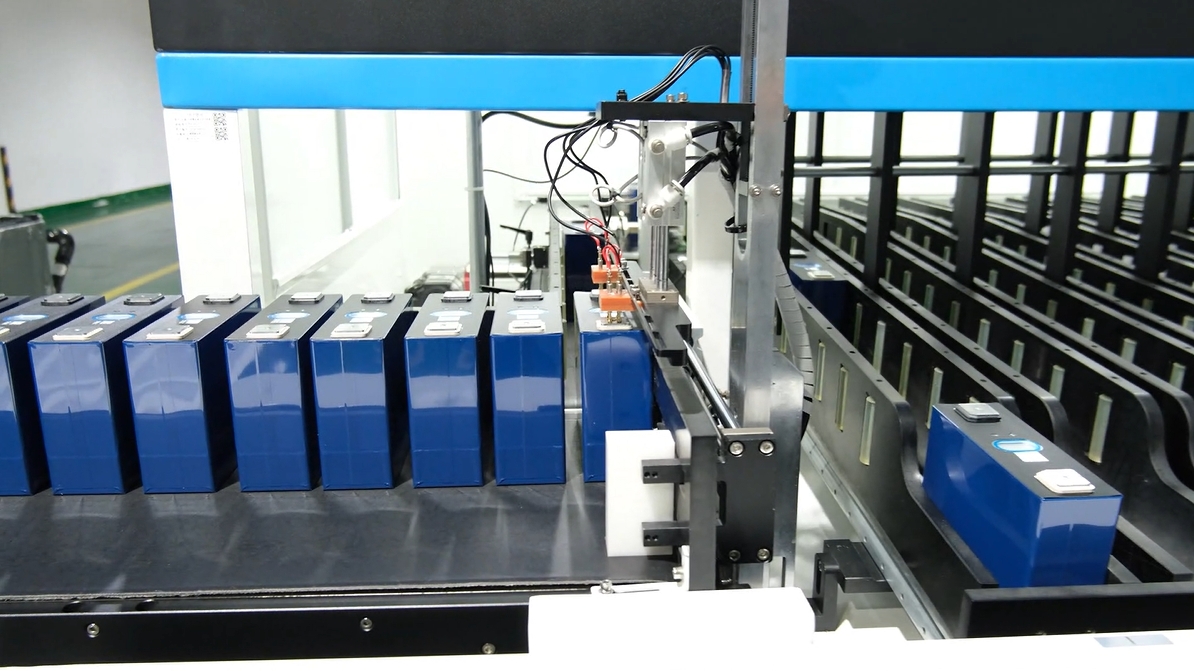

- Cell Assembly: During cell stacking or winding, electrode alignment and separator integrity are continuously verified. In prismatic cell assembly, robotic systems ensure geometric precision, maintaining consistent performance across cells.

- Formation and Aging: Cells undergo initial charging/discharging cycles, known as formation, to stabilize capacity. This stage identifies defective units early, ensuring only high-quality cells progress.

- Battery Cell Inspection Process: Each cell is scanned for internal shorts, dimensional accuracy, impedance variation, and voltage irregularities. Faulty cells are automatically rejected or reworked.

- Module and Rack Assembly: Cells are assembled into modules and racks. Electrical balancing and mechanical integrity are checked using thermal imaging and resistance measurement techniques.

- Rack-Level Battery Testing: The assembled rack undergoes charge/discharge tests, temperature monitoring, insulation resistance tests, and BMS communication validation. Simulated environmental tests are also conducted to confirm robustness.

By enforcing rigorous standards at each step, manufacturers ensure battery safety and reliability testing are not just reactive measures, but embedded throughout the production lifecycle. This ensures all energy storage systems meet strict tolerances and performance expectations, no matter the scale of deployment.

Common Manufacturing Defects and How They Are Prevented

Lithium-ion battery manufacturing defects can originate at various points along the production line. Some of the most common include:

- Contamination: Dust, metal particles, or humidity during cell assembly can cause internal short circuits. Cleanroom assembly lines minimize this risk using HEPA filtration systems.

- Misalignment: Incorrect electrode placement leads to uneven current density and reduced cell performance. Precision robotics and optical guidance help avoid these errors.

- Electrode Thickness Variation: Uneven coating thickness affects energy output and lifespan. Automated laser profilometers measure layer consistency in real time.

- Seal Failures: Poor welding or sealing of the cell casing may result in electrolyte leakage or exposure to air, which degrades battery chemistry. Ultrasonic welding and X-ray verification are used to ensure seal integrity.

- Capacity Mismatch: Inconsistent capacity between cells affects pack balance and performance. Capacity testing and sorting are performed before modules are assembled.

To prevent these issues, manufacturers implement cleanroom environments, precision robotic handling, inline laser inspection, and automated X-ray diagnostics. Advanced imaging systems detect micron-level deviations, ensuring only compliant components move to the next stage.

In addition, predictive analytics and AI-integrated quality control systems are increasingly used to flag potential defects based on historical data patterns. Machine learning models can forecast likely failure points, helping technicians intervene before defects occur. This proactive approach in battery production line QC reduces yield loss and enhances consistency across manufacturing batches.

Industry Standards and Certifications for Battery Quality Assurance

Global lithium battery manufacturers must adhere to established industry standards to ensure product safety and quality. These certifications provide assurance that products meet performance and regulatory benchmarks:

- ISO Certification for Battery Systems (ISO 9001/14001): Focuses on quality management and environmental responsibility. Certification demonstrates organizational maturity and process standardization.

- UN38.3: Required for shipping lithium batteries, involving tests like altitude simulation, thermal shock, vibration, and impact. This standard prevents transportation-related incidents.

- UL 9540A: Tests battery system thermal runaway potential, especially for energy storage installations. UL certification is increasingly required for commercial ESS deployments.

- IEC 62619/62133: Sets safety requirements for rechargeable lithium cells used in stationary storage and portable applications. Compliance here ensures grid compatibility and safety.

- CE and RoHS Compliance: Ensures conformity with EU regulations on safety, health, and hazardous substances. Mandatory for access to the European market.

Meeting these standards often requires third-party audits and testing. Certification not only validates the effectiveness of quality assurance in battery production but also facilitates entry into international markets and ensures compliance with local grid integration policies. Customers and project developers often use these certifications as prerequisites in supplier evaluation, making them vital for competitiveness.

How Reliable QC Boosts Battery Safety, Lifespan, and Performance

Reliable lithium battery quality control enhances all critical aspects of energy storage systems: safety, lifespan, and performance. Consistency in the manufacturing process ensures that cells within a battery pack operate uniformly, reducing stress and thermal imbalance.

- Safety: High QC standards prevent internal shorts, overcharging, and thermal runaway events. Systems are equipped with multi-layer safety controls—from internal fuses to software-based protections.

- Lifespan: Uniform electrode structure and electrolyte distribution result in even aging across cells, maximizing usable cycles. Batteries with high-quality QC maintain their capacity over time.

- Performance: Accurate capacity matching and precision balancing enable stable voltage output and high efficiency. This is vital in applications such as grid support or industrial peak shaving.

For example, Hicorenergy integrates advanced monitoring systems during both cell and rack-level testing. By using automated BMS diagnostics, remote system analytics, and integrated protection protocols, every battery unit that leaves the factory is built to perform reliably under diverse operational scenarios.

In a sector where failure can result in fires, data loss, or grid instability, rigorous QC isn’t just a technical requirement—it’s a market differentiator. Buyers, whether residential users or utility-scale developers, rely on tested systems that deliver consistent, safe, and high-efficiency energy storage over the long term.

Trust quality from the start—contact us to learn how our lithium battery systems exceed global QC standards and deliver reliable energy performance.

Email: service@hicorenergy.com

WhatsApp: +86 181 0666 0961

Direct Call: 0574-8796-6601